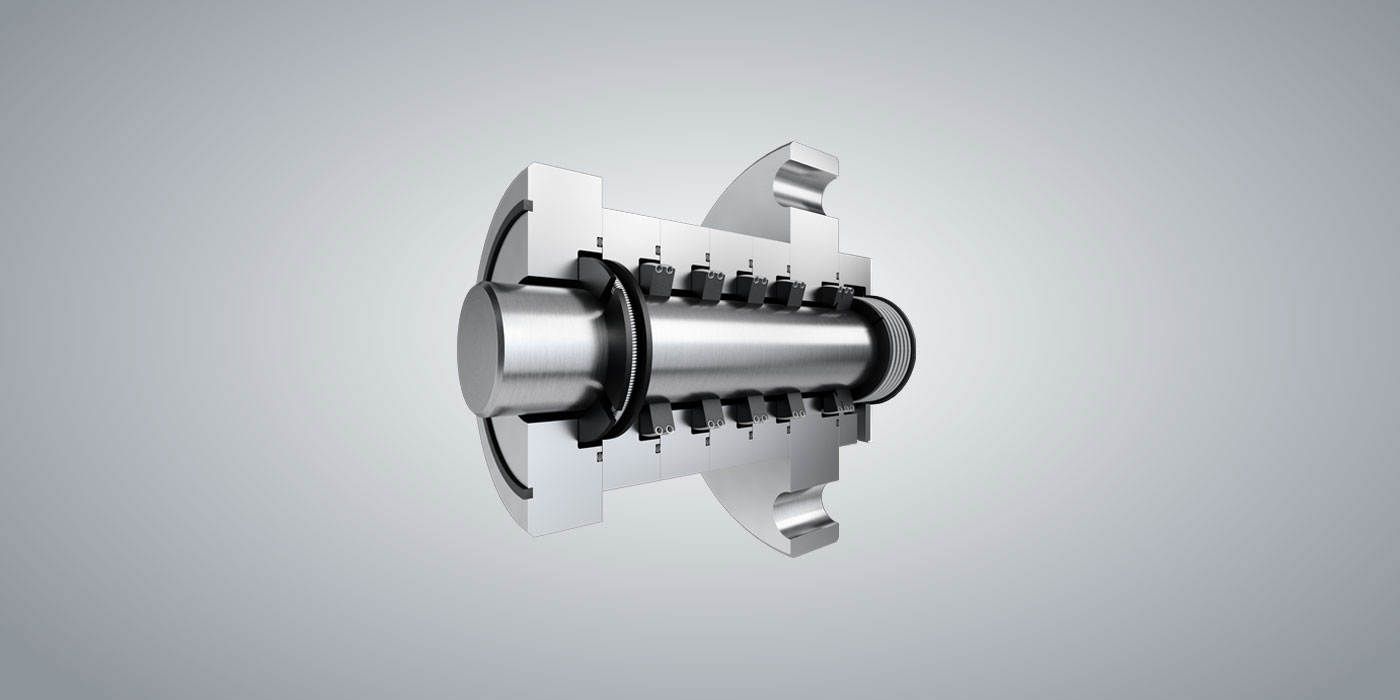

CPC – Compact Packing Case

Sealing at its best for small units

Performance without compromise

Don’t let their small footprint fool you – small compressors used in the natural gas sector can be significant sources of harmful methane emissions, resulting in hefty fines under new regulations. Small compressors deserve the same level of build quality and materials as their larger counterparts used in refineries and petrochemical plants. Recognizing this, we are committed to providing a solution that focuses on value-conscious design, striking the perfect balance between superior quality and efficient design to prevent unnecessary budget strain on your small and medium size compressors.

Cup-to-cup leakages belong to the past

Cup-to-cup leakage can result in significant emissions, especially when surface quality is compromised over time due to wear and tear. The design of the CPC Compact Packing Case employs smartly designed, standardized stainless steel cups that can be adapted to multiple compressor geometries and different makers. The O-rings ensure tightness between packing cups and are forgiving of surface roughness, unlike conventional packing cases that require lapping in a professional repair shop. The maintenance of the CPC is particularly easy, because now the packing can be returned to brand-new state directly in the field without special tools.

HOERBIGER’s CPC -

Compact Packing Case is the rod packing solution designed with a green mindset

We also believe in minimizing our carbon footprint beyond just reducing direct emissions. Our Compact Packing Case is manufactured with the utmost care to reduce the use of raw materials and energy, and waste during production (Scope 3-emissions*). The result is a product that is not only reliable and efficiently manufactured but also eco-friendly, from the factory to the field.

Components intelligently connected

CPC can also be used as a combined packing, as CPC can be connected with HOERBIGER’s best performance-determining components such as BCD Emissions Elimination Rod Rings and the WME Multi-Edge Wiper, in an intelligent design. So, oil wipers and the pressure packing are integrated in one single device. This no-frills packing is specifically tailored for small compressors which do not employ a distance piece (up to 65 mm rod diameter), which makes it unique.

*according to Greenhouse Gas (GHG) Protocol

Scope 1: Direct release of climate-damaging gases in own company

Scope 2: Indirect release of climate-damaging gases by energy suppliers

Scope 3: Indirect release of climate-damaging gases in the upstream and downstream supply chain

Your benefits at a glance

| Feature | Advantage | Benefit |

|---|---|---|

| Long component live | Less maintenance, less repair, and less spare parts | Enhanced productivity |

| O-rings sealing cup-to-cup surfaces | Field repair possible | Increased efficiency |

| Case built in stainless steel | Corrosion resistance material results in permanently reliable sealing performance and is suitable for non-lube operation (e. g. Biogas, PET) | Higher reliability |

| Standardized design for small and midsize compressor | Minimize raw material, energy and waste to reduce carbon footprint (Scope 3 emissions*) | Complying your emissions requirements |

| Compatible with BCD Emissions Elimination Packing Ring | Best in class gas sealing performance | Reduction of emissions throughout the product lifecycle |

| Compatible with WME Wiper Multi-Edge | Best in class oil sealing performance | Stop of oil leak from the crankcase and potential secondar |

Brochure A4 Format

Brochure Letter Format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.