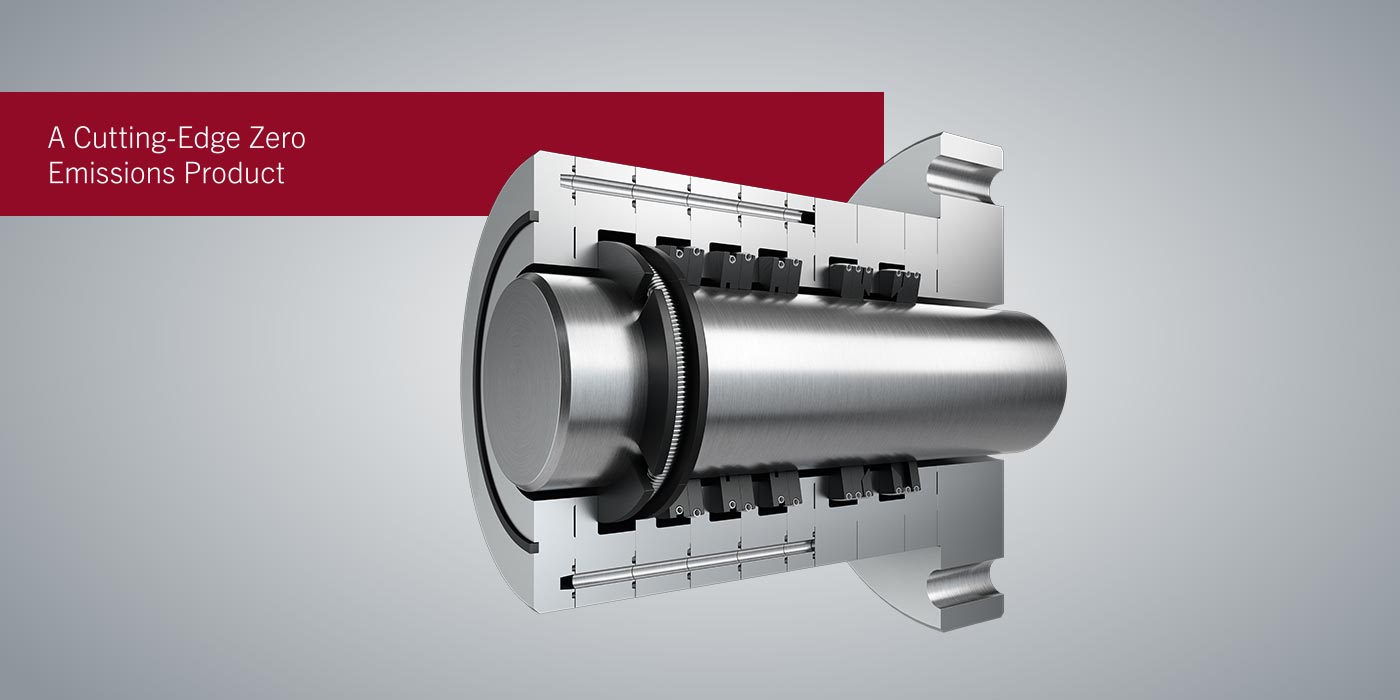

BCD – Emissions Elimination Packing Ring

Reduce gas leakages and increase lifetime

More efficiency, less fugitive emissions

Piston rod packing is the primary source of emissions generated from reciprocating compressors. The rings inside the packing seal the gas around the moving piston rod, preventing it from escaping the cylinder. Conventional packing rings work in pairs, each ring covering the gaps in the adjacent ring. However, this still leaves microscopic escape paths between the rings, where the gas can leak.

Our Emissions Elimination Packing Ring (BCD) seals the piston rod to prevent gas leaks during the compressor operation. With up tp 70% leakage reduction, fugitive emissions can be reduced drastically. Combining two rings into one eliminates the disadvantages and reliability issues associated with conventional two-ring designs. The main segments seal the piston rod and form a gap to compensate for wear. BCD extends your maintenance intervals and eliminates downtime due to premature wear. Therefore, the design saves both: material and safeguard the environment.

By replacing conventional rings with BCD, we were able

to extend the maintenance intervals, and above all greatly reduce fugitive emissions which will bring us one step closer to our goal of protecting the environment.

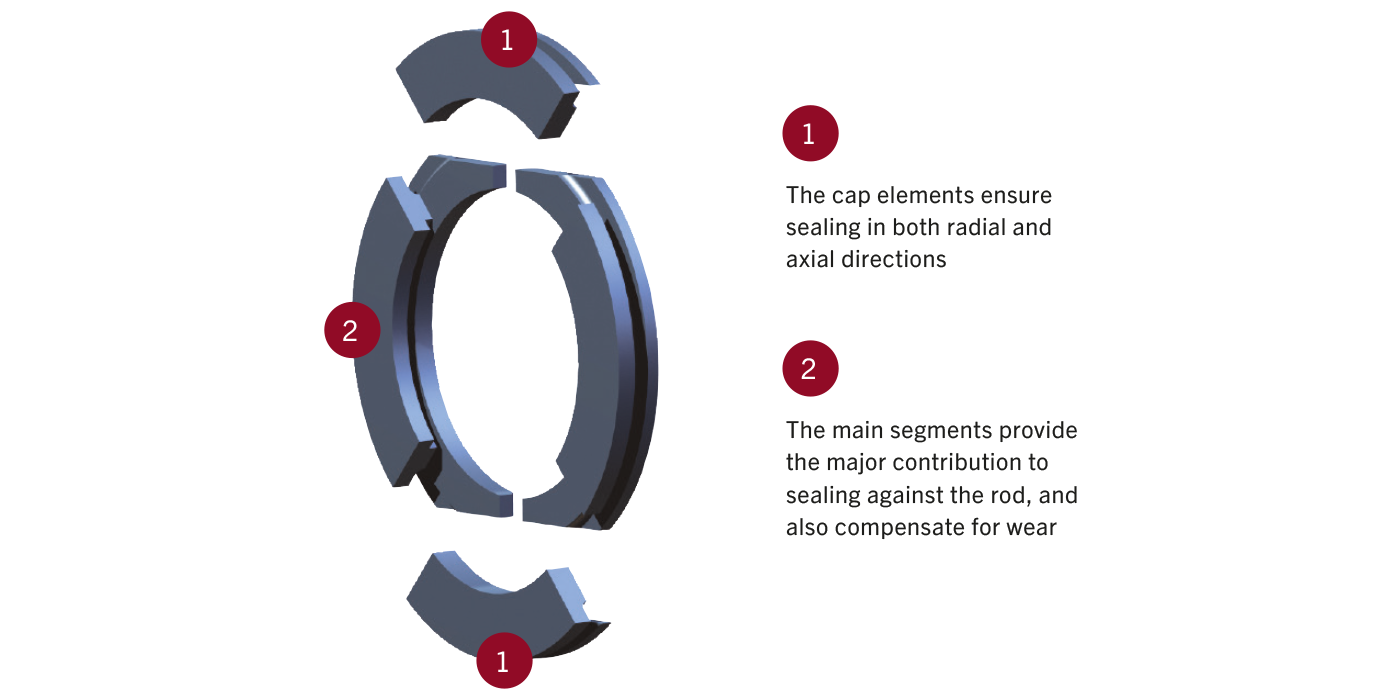

Functional principle and design advantages

The Emissions Elimination Packing Ring uses a pressure equalization groove to reduce contact pressure. The main segments seal the piston rod and form a gap to compensate for wear. The cap segments seals in axial and radial directions which ensures pressure equalization and guarantees high efficiency over the entire service life. The narrow design reduces friction which leads to lower heat generation and wear. In addition, the seal is shorter than conventional pressure packings.

- Significantly reduced gas leakages protect the environment

- Up to 70% leakage reduction helps operators meet stringent emission standards and reduce gas losses

- Low frictional resistance: Saves energy and may eliminate the need for water cooling

- Reduced wear: Increases reliability and service life

- Easier ring replacement simplifies maintenance

- Piston rod diameter:

- 20 mm (0.78 inches) to 140 mm (5.51 inches)

- Pressure range:

- 3-250 bar

- Fields of application (extract):

- Process gas:

- Refining, petrochemical industry, chemical industry

- Oil and gas:

- Gas lift and re-injection, gas storage, LNG terminal, gas gathering, gas transportation, CNG

- Industrial gases:

- Syngas (hydrogen, carbon oxide), air separation (oxygen, nitrogen), specific gases (argon, helium,…)

- Food industry:

- PET bottle blowing, industrial air

- Power generation:

- Cogeneration, combined heat and power plant, biogas

Brochure

Brochure letter format

Brochure A4

Brochure Letter format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.