XperLUBE – Digital Commonrail Lubrication

Mastering cylinder lubrication andcompressor reliability

Reliable cylinder lubrication is one of the most sensitive topics in the operation of reciprocating compressors. Incorrect oil metering can cause damage through both under- and over-lubrication. This, in turn, means unplanned downtime, costly production losses, or consequential damage elsewhere in the process.

Your lubrication experts

HOERBIGER developed XperLUBE to boost the performance and cost efficiency of your compressors. XperLUBE supplies your system with exactly the right amount of lubricant. At all times. Under any conditions.

XperLUBE: modern lubricant management

Whether your lubrication issues stem from temperature, pressure, speed, or the failure of lube ports:

- XperLUBE is faster and more precise than manual control

- XperLUBE automatically supplies exactly the right amount of lubricant to suit your specific requirements and the current operating conditions

- When the process changes, the lube rate changes

- Ambient temperature:

- -25°C to 60°C (up to 95°C for injectors)

- Cylinder gas pressure maximum:

- 375 bar

- Max speed:

- no restriction

- Certificates:

- ATEX, IECEx

- Conforms to API 618:

- yes

Easy installation and integration

- “Plug-and-Play” cylinder and packing lubrication system

- Easy diagnostics to find malfunctioning injectors

Efficient and reliable operation

- Precise and reliable lube rate management

- No unplanned shut downs due to compressor damages caused by under- or over-lubrication

- Real-time automated monitoring, control and adjustment of oil flow rates for each lube point

Simple and inexpensive maintenance

- Standardized parts for all compressors and applications

- System components can be individually and quickly replaced

- Inspection intervals of the injectors are individually adjusted to maintenance intervals of the compressor

Simple setup, maximum effect:

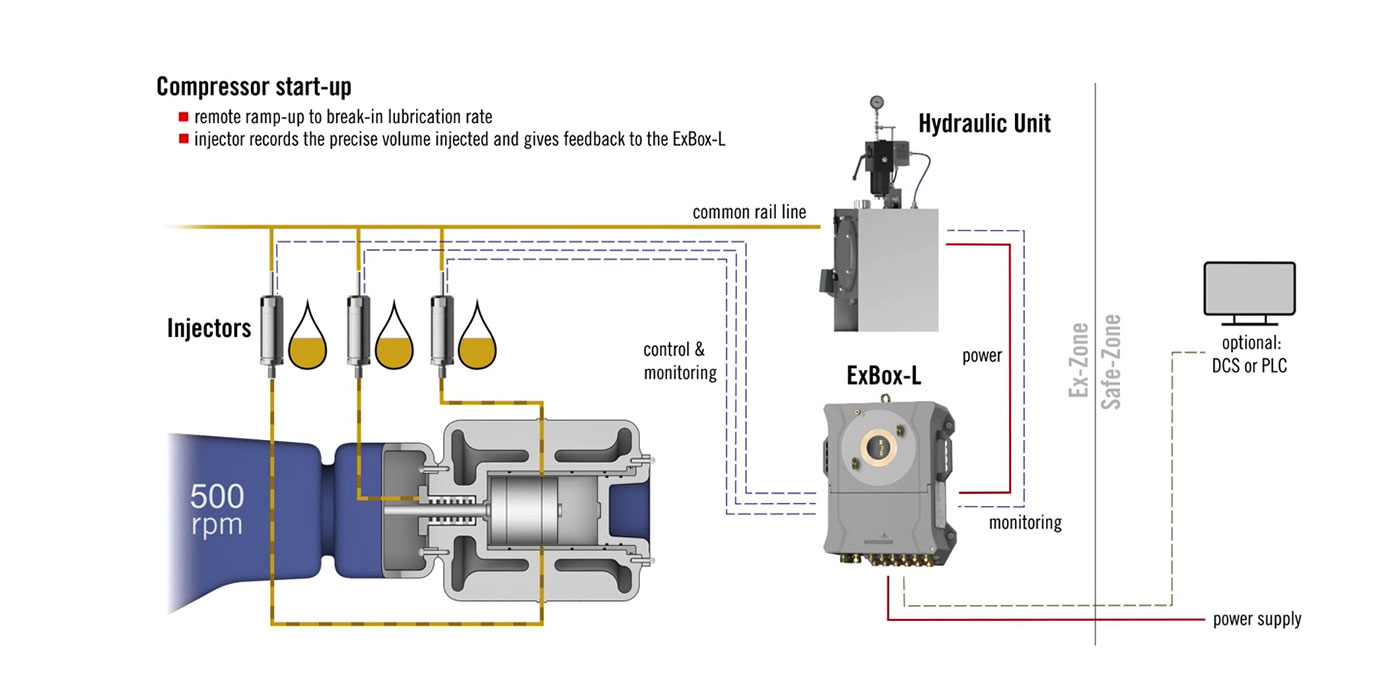

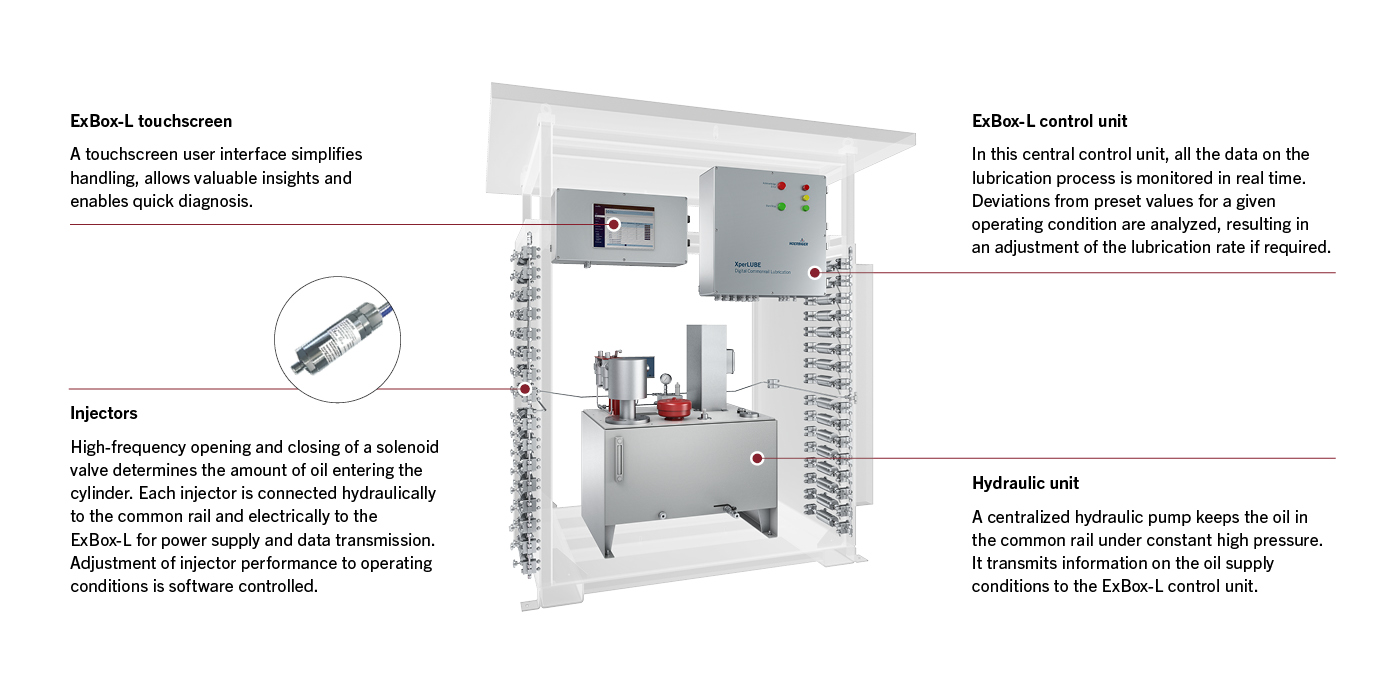

The XperLUBE system unites value-adding functionalities with easy integration and maintenance. The idea behind XperLUBE is simple. By disconnecting the oil pressure generation from the process of injecting oil into the cylinder, lubrication precision is greatly increased. A high-pressure common rail supplies oil to the lubrication points. Metering and injection is achieved with injectors, one at each lube point. At the center of the system, a control unit monitors the performance of all injectors and adjusts lubrication rates according to preset parameters. The same injector and hydraulic unit models are used in all applications.

System layout

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.