We Create Heartbeat Moments

Our Piezo Valve achieves 1.000.000.000 switches with only a strawberry’s energy.

The piezo chip only needs 20 µJ for a circuit. The lowest power requirement of any electric controller on the market. The energy of a strawberry keeps the piezo for an unbelievable billion switching operations! Durability at its finest.

Our Piezo Valve switches in 0,001 seconds, 20 times faster than a hummingbird’s flap.

That‘s really fast! Ultra fast! The reaction and switching time of a piezo chip is invisible to the human eye.

If a hummingbird flaps its wing once, the HOERBIGER Piezo Chip can perform 20 operations in the same time. He‘s just our high speed performer.

Our Piezo Valve is infinitely accurate in pressure output. The best watches achieve ±2 seconds accuracy per day.

As precise as a Swiss clockwork.

Tecno

Piezo-controlled pneumatic pressure regulator

- Low weight and low electric emission

- No heat generation

- Regulation from 0 bar provides exceptional control flexibility

- High regulation stability and resolution ensures improved output quality

- Rapid cycle capability provides improved productivity

- Low power consumption enables the way for a better sustainability

- Ease of installation and compact dimensions affords design flexibility

- Function

- 3-way-proportional pressure

- Flow Capacity

- Up to 1.6000 l/min

- Pressure Ranges

- -1 to +16 bar

- Accuracy

- Better than 0,5 %

- Reaction Time

- < 7 ms

- Supply

- 24 VDC

- Medium

- Every medium is possible due to seperation of control & process medium

Technical data sheet

Technical data sheet

Technical data sheet

More information on our Tecno products you can find here.

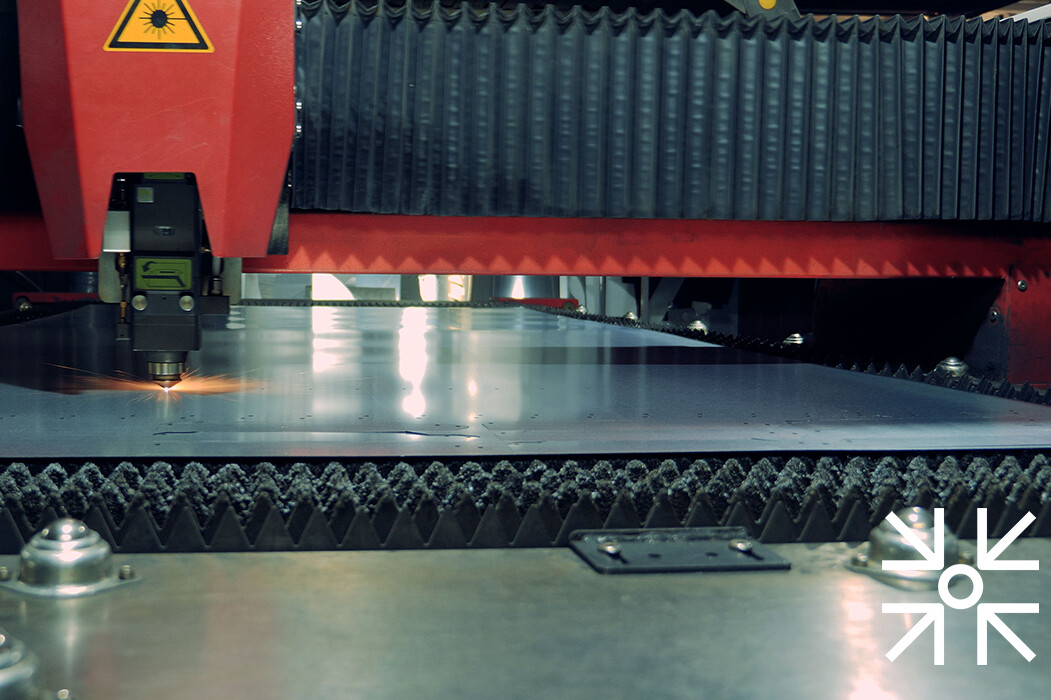

lasgar

Laser Gas Regulator for laser cutting machines

- Increase the speed of your laser cutting machine

- Improve your cutting quality

- Make the condition of your gas pressure visible and smart with our Bluetooth connection

- With our LasGAR toolbox you are very flexible and you can adapt it individual

- Flow Capacity

- Up to 9.300 l/min

- Pressure Range

- 0,4 - 30 bar (output)

- Accuracy

- +/- 0,06 bar

- Reaction time

- < 7 ms

- Supply

- 24 VDC

- Medium

- Tpical Oxygen, Nitrogen, compressed Air, Argon

- Weight

- 0,6 - 3,45 kg

Product information

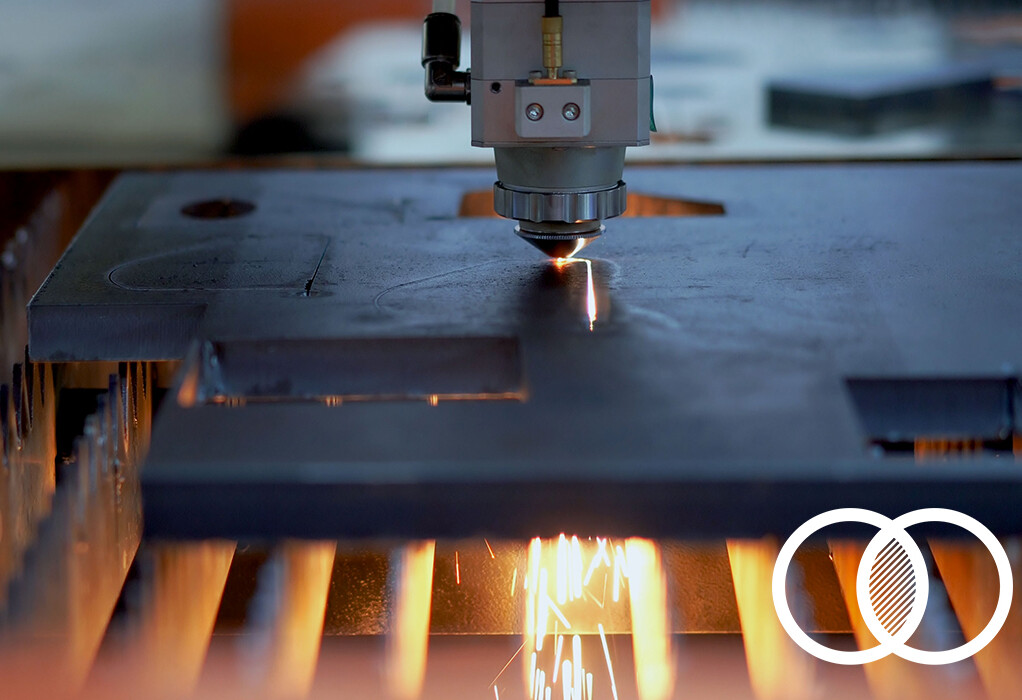

LasGAM

Piezo-controlled Gas Mixing System

- You increase your productivity by up to 50 %

- You reduce your cutting gas consumption by up to 55 %

- Simple installation with our tankless design

- You get reliable cut quality through uninterrupted status monitoring with our Bluetooth connection and app

- Flow Capacity

- Up to 9.300 l/min

- Pressure Range

- 0,4 - 30 bar (output)

- Reaction Time

- < 7 ms

- Accuracy

- +/- 0,25 % abs

- Repeatability

- +/- 0.007 % abs

- Supply

- 24 VDC

- Typical Oxygen, Nitrogen, compressed Air, Argon

Piezo-controlled Gas Mixing System

Datasheet

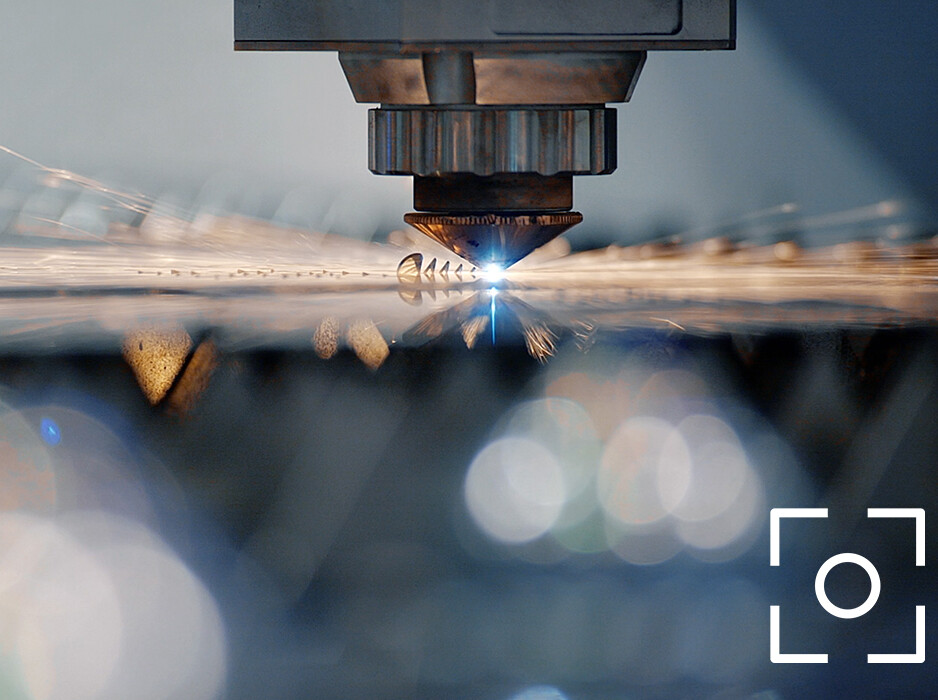

Adjust the focus in laser cutting heads

Application

- Variable adjustment of the laser power in the cut

- Keep the speed and dynamic also in curves high

- Super lightweight solution to get higher speed in your X-, Y- and Z-axle

- Precise and fast adjustment of the focus during the cut

Highest pressure control without Stress

Application

- LasGAR is used to control the gas pressure in the Laser Cutting machine

- LasGAR can switch between up to 4 different applied gases

- The maximum regulated gas flow provided through the LasGAR is reducing the burr and increases the cutting speed

- P9 piezo valves enables the LasGAR extremely high number of switches over lifetime

Join the evolution with LasGAM!

Application

- Safe costs and energy with our LasGAM because you are able to reduce the gas consumption up to 55 %

- With the LasGAM gas mixing unit it is possible to add a definable proportion of oxygen to the cutting gas nitrogen and thus reduce the “rough” cutting edge and increase cutting speed!

- Reduce the oxide layer compared to pure oxygen cutting

- You could weld and coat directly after the cut

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.