How does...

... an overload clutch work?

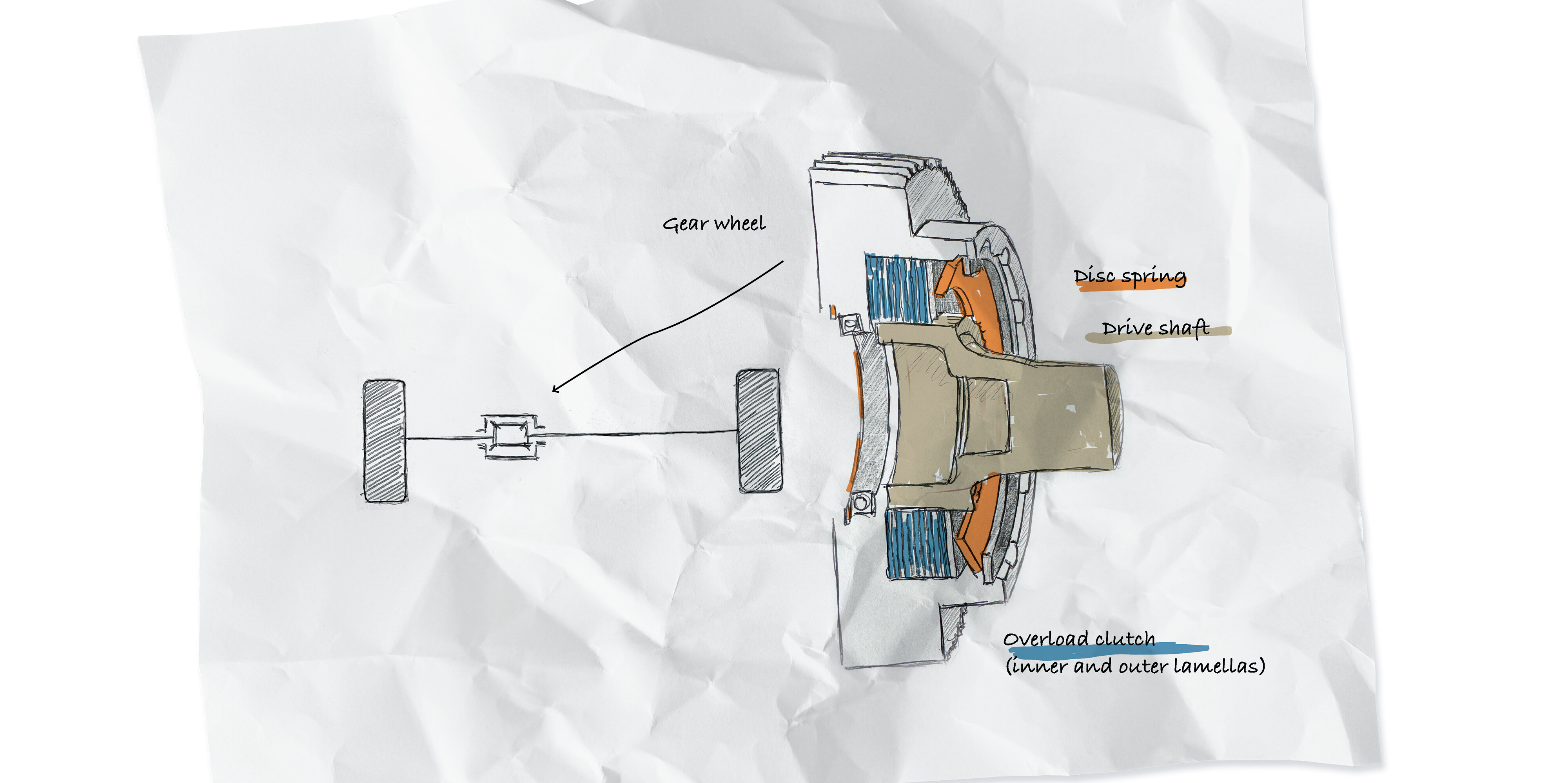

In electric drives, a small but cleverly engineered component known as an overload clutch protects the electric motor and transmission from damage caused by sudden overloads. We spoke with Konrad Lory, Product Manager and Head of Technical Sales in the Automotive Division, who explained the principle behind this intelligent protection mechanism.

Konrad, what is an overload clutch?

Konrad Lory — Imagine two gears firmly connected to one another. If too much force is suddenly applied, something could break. The overload clutch prevents exactly that – in such moments it yields in a controlled way and protects surrounding components. You can think of it as an integrated safety mechanism. This particular clutch was developed in collaboration with an automotive customer who wanted to address precisely this issue in the drive system, and HOERBIGER provided the right solution.

Can you explain how it works in more detail?

KL — Inside the clutch are several steel discs and a so-called disc spring that hold the components tightly together. If a defined force threshold is exceeded, the clutch “slips” – power transmission is interrupted, and sensitive components remain unharmed. For example, this could happen when a vehicle drives over a high curb: the wheel briefly loses contact with the ground and then regains traction abruptly.

Can an overload clutch be compared to a standard clutch?

KL — Not really. A standard clutch connects or disconnects two components on purpose – for instance, during a gear shift. The overload clutch, by contrast, only activates in an emergency – when something goes wrong. It’s technically sophisticated, but when it’s needed, it makes all the difference.

Are overload clutches used in other applications as well?

KL — Yes, especially in environments where high forces are involved, such as in industrial facilities. There, too, overload clutches help prevent damage to motors, gearboxes, and other critical components, significantly contributing to the safety and efficiency of the overall system.

What makes a good overload clutch?

KL — The interaction between materials is key. The surface quality of the steel parts, the characteristics of the spring, and the type of oil used all have a major impact on service life and performance. The clutch will only function reliably when all the components are perfectly matched.

“The surface quality of the steel parts, the characteristics of the spring, and the type of oil used all have a major impact on service life and performance of an overload clutch.”

Automotive Division